By Jo Miller

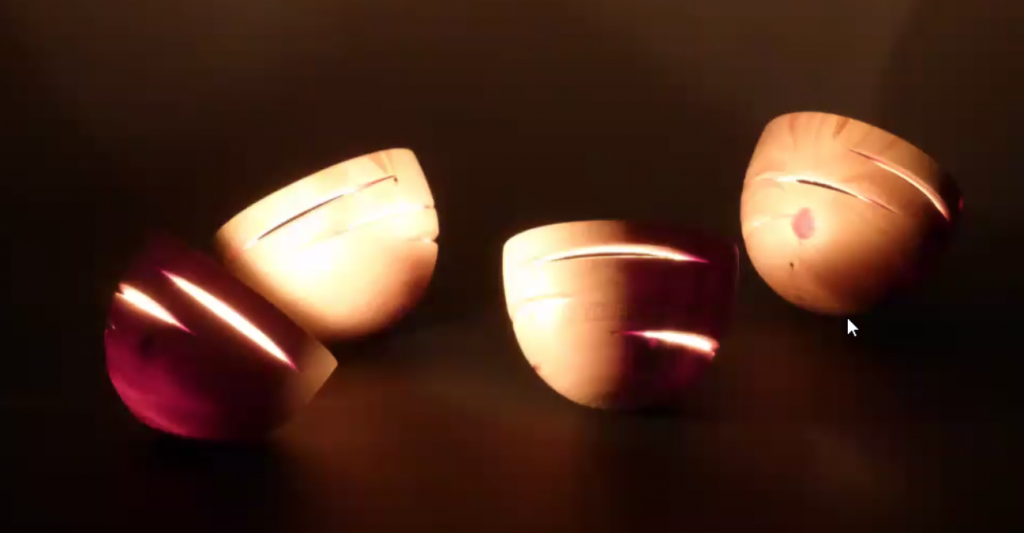

Laurent Niclot demonstrated turning a small votive bowl that lies off-center, with eccentric slits to allow the light to shine through . He began with an end-grain piece of green olive wood ~ 2” long x 1.5” in diameter. He placed the wood between centers and rounded the piece using a roughing gouge. He prefers to use a bedan (3/8” or 3/16 rectangular tip) for most of his shaping which he feels produces in the cleanest surface. He also used and explained how to use a Vicmarc #3 Escoulen chuck to enable him to move the bowl off center and create the slits on only one side of the bowl. While this is an expensive chuck (~$425) he felt it was this most stable for off center work. The Sorby chuck is less expensive but not as heavy – so might be OK for smaller pieces.

A tenon was turned to fit the cup chuck – which was then hammered into the chuck. Once the wood was in the cup, the began shaping the bottom of the bowl using the edges of the bedan tool with his arm at first farther away from his body and then rolling into his side. He also demonstrated how a spindle gouge with a long sweeping edge could also be used for this shaping.

Once the bottom of the bowl was shaped, the cup was then moved away from the center of the chuck and the counter weights adjusted to maintain stability while the wood was spinning at a fast speed. For safety, the live center was engaged with the top of the bowl. With the cup at the farthest position from the center and the tool rest adjusted, a slit was cut in the wood ~ 3/8” from the top edge and shaped slightly. The slit should be deep enough so that once the bowl is hollowed, the slit will go through the side of the bowl. Once this first slit is made, the bowl is moved 2 mm closer to the center and another slit is made in the middle of the bowl in the same way. Again the bowl is moved 2mm for a 3rdslit near the bottom of the bowl. The slit at the top of the bowl will be longest and the bottom slit the shortest.

The bowl is hollowed with the cup of the chuck in the center position. Laurent demonstrated the use of several tools for the hollowing process. With a spindle gouge the handle should be parallel to the wood and moved from center to the outside edge. This prevents tear outs with straight-grained wood blanks. A bowl gouge should have the handle low and move from a 12 to 2 o’clock position – still starting in the center. The bowl gouge is less aggressive than the spindle gouge. A hook tool can also be used which is a good tool for end grain but you need a hole in the middle. The tool rest must be farther away and the hook cuts with only one bevel. A rounded scraper can also be used and may be the easiest to use. Continue hollowing until all three cuts are visible through the wall of the bowl and the thickness you want.

Once the bowl is hollowed, continue shaping and rounding the bottom of the bowl. Leave a small triangular shape at the bottom and cut from the tenon on the far side of the triangle to prevent any tear out at the bowl bottom. Remove the rest with a hand chisel and sand to smooth the bottom.

To finish, sand and let the bowl dry several days. Make a flat side by sanding on the side opposite the slits. You don’t was it too tilted to prevent a flame from the tea light from burning the inside of the bowl. Once dried, finish with a hard oil 2-4 coats or a mixture of wax (20%) and grape seed oil (80%). Do not use lacquer because of the flame.

Remove the tenon from the chuck using either 1) a knock out bar if its small enough, 2) wait for the wood to dry and it will loosen enough to tap it out or 3) cut away the wood with a bedan until their is only a thin piece, cut through the bottom with a bowl gouge, then use a spindle gouge to scrape the inside until you can break off and pull off the thin ring of wood left in the chuck.

Tool resources

Bedans – 5×9 mm; 10×10 mm; 12x12mm – Woodworkersemporium.com

Hook tool (Hosuluk) – woodturningtoolstore.com

Vicmark #3 Escoulen chuck – V00295#3 – woodworkersempoium.com